Vapour cycle cooling system in aircraft

Explain the vapor cycle cooling system used in aircraft with neat illustration. Also explain the physics behind the scene of working.

Physical principle

Liquids can be vaporized at any temperature by changing the

pressure acting on it. To clearly understand this concept, we will take

an example of water contained in a vessel. When the vessel is at atmospheric

pressure, the water will be boiling at 100°C when heating. If I am pressurizing

the vessel to more than the atmospheric pressure, then water will not boil at

100°C. If I am creating a drop in pressure in the vessel by a vacuum pump, then

water will boil at a temperature less than 100°C.

Basic law of thermodynamics states that heat will always flow from

hot body to cold body. If I need a reverse of this, I have to add some work.

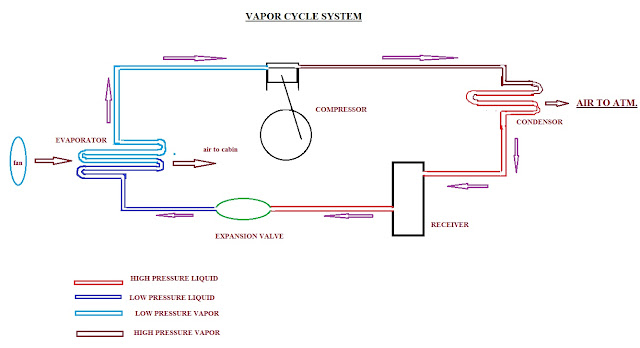

System operation:

1. We are having the FREON as refrigerant in the vapor cycle

cooling system. It has a boiling point of 4°C.

2. At the receiver I am having high pressure, so that FREON will

have high boiling point.

3. When the vapor cycle system is switched on, the compressor

starts delivering the pressure and thus making flow.

4. The highly pressurized FREON at the receiver is in liquid

phase. When the Freon flows through the circuit, first it expands at the

Expansion valve. So pressure has been dropped (i.e. Boiling point decreased).

5. The less pressure Freon then goes to the evaporator stage.

Evaporator will be exposed to Cabin. We blow the warm air of cabin over the

evaporator coils by fan, and thus doing a forced convection.

6. The heat transferred to the Freon makes it to change the phase

which is from liquid to vapor.

7. The less pressure Freon vapor is then compressed by the

Compressor and thus it delivers high temperature high pressure Freon vapor.

8. Now this high pressure and high temperature Freon vapor enters

the Condenser coils where the cool air from atmosphere will be blown over the

coils (here too making a forced convection). Condenser will be exposed to the

Atmosphere. Because of heat transfer the Freon losses heat and returns to

liquid phase.

9. Then it goes to the receiver (high pressure low temperature

Freon liquid)

10. The cycle continues as stated. Before doing any type of

maintenance activities to the vapor cycle system, we have to purge the system

with inert gas in a open atmosphere.

11. Freon is colorless, odorless, and non toxic; however, being

heavier than air, it will displace oxygen and cause suffocation. When heated

over an open flame, it converts to phosgene which is deadly!

12. To know the Freon level in the circuit a sight glass

arrangement will be employed between Receiver to Expansion valve. If the unit

requires additional refrigerant, bubbles will be present in the sight glass

otherwise steady.

Note:

When using this method air conditioning, pressurization have to be

done separately, either by using Cabin superchargers or Engine driven

compressor or by using your future design that delivers pressure with least

energy taken as input.

good !

ReplyDeletecan you a T-s diagram of the above cooling system?

DeleteI was pinning away for such type of blogs, thanks for posting this for us.vaping

ReplyDeleteIn summers we needs comfort and cool air for refreshing our minds we are talking about air conditioner installation Toronto in the middle of the summer the weather is very hot and everyone is getting rid of it that’s why they use the services of air conditioning.

ReplyDeleteNice post many thanks for sharing the blog, It's very nice I am very much interested in learning looking for more updates. Refrigerant gas suppliers

ReplyDeleteWow that was odd. I just wrote an extremely long comment but after I clicked submit my comment didn't appear. Grrrr... well I'm not writing all that over again. Anyhow, just wanted to say great blog!

ReplyDeleteEspar Heater

thanks for writing this post.it was really interesting.i will keep visiting your blog.check our Heating and Cooling Service Pembroke

ReplyDeleteGood

ReplyDeleteOffering the efficient solutions to the consumers with trust worthy policies, we don’t compromise on qualityiqf freezer manufacturers in chennai

ReplyDeleteAlaquainc, which specializes in designing and manufacturing a broad range of different evaporator systems designs to fulfill diverse client requirements.

ReplyDeleteShock Testing Machines of various capacities to be used in the design and destructive testing of components, hybrids, circuits, and complete assemblies. These machines are used testing a variety of products from Aerospace, Millitary, Industrial and consumer

ReplyDeleteShock Testing Machines

very informative post .Thanks for sharing post

Climatic Test Chambers

Environmental Chambers for simulation of conditions like temperature, humidity, corrosion, dust and rain to be used for various tests.Jost's provide the latest generation of Climatic Test Chambers with innovative technique and future-oriented design.

Battery testing equipment determine the condition of lead-acid and nickel-cadmium cells ,String, Battery capacity, Electrical power. Robust,repeatable instruments, Measures float and ripple currents.

Nice blog post

ReplyDeleteThanks for sharing the post! R600a

ReplyDeleteThis information is impressive; I am inspired with your post writing style & how continuously you describe this topic.

ReplyDeletesolar panel installers Kent

Very great post. It's really very informative. I am hoping you write again very soon.And if you need more information about evaporative air cooling system you can check out my page also. It will help you.

ReplyDelete"Wow, I came to learn about machines, and your information is absolutely amazing! For more insights and if your are looking for the Visit veeaarengineering!We specialize in reliable solutions to meet all your industrial needs. Keep up the great work!"

ReplyDeleteRely on the best panel air conditioners by visiting Panel Air Conditioners Supplier.

ReplyDelete