Aircycle cooling system in aircraft

Why we need aircraft's cabin

pressure and temperature to be controlled?

At atmospheric condition we have sufficient pressure to breath

freely. As the altitude increases pressure drops. Till 8,000 ft altitude the

pressure variation won’t affect us but beyond that we will get affect

(hypoxia), so in order to have same pressure to breath freely in the cabin of

aircraft, we need to go for maintaining the pressure artificially.

As like pressure temperature also drops as the altitude increases,

but up to certain layer of atmosphere which is stratosphere. Most of the

aircraft are operating within Stratosphere. So we need to have a constant

temperature in our cabin, so that passengers feel the comfort of their

travel.

What are the methods in practice for maintaining cabin pressure and

temperature?

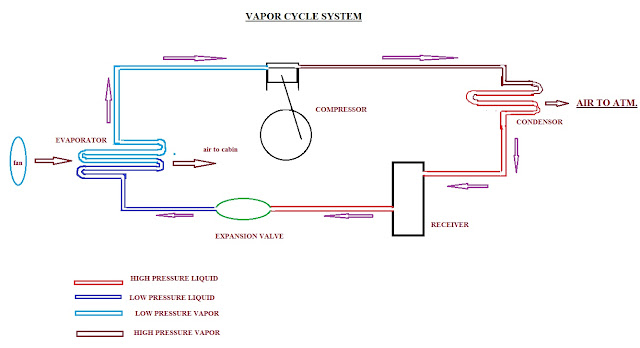

Air cycle system

Vapor cycle system

Explain Air cycle cooling system of cabin atmosphere control with neat figure?

. Left

engine

2. Right

engine

3. Flow

limiter

4. Primary

heat exchanger

5. Primary

heat exchanger bypass valve

6. Shut

off valve

7. Compressor

8. Secondary

heat exchanger

9. Water

separator

10. Secondary

heat exchanger bypass valve

11. Refrigeration unit

1. Air from the compressor sections of the two engines is taken

for air conditioning and pressurization. We are making a cross connection so

that it can supply uniform flow of air.

2. Air is going to the flow limiter. Flow limiter limits the

amount of compressed air to entry into the system. Suppose if there is any

pipeline ruptured in air cycle system, then flow limiter won’t allow the compressed

air to enter into the air cycle system.

3. Partial amount of air from the flow limiter goes to the primary

heat exchanger. Primary heat exchanger utilizes ram air for cooling purpose.

The compressed air taken from the engine compressor may be at temp range of 200

deg to 400 deg Celsius. We are cooling the air without reducing much pressure

by using heat exchanger, and heat exchanger works on Convective type.

4. Another amount of compressed air from flow limiter goes to

mingle with the heat exchanger outlet air to make a constant temperature air of

300 °F. This constant temperature can be attained only by proper operation of

Primary heat exchanger (PHE) bypass valve. For example if heat exchanger outlet

air is at 200°F, but I need an output of 300°F at outlet portion of Primary

heat exchanger bypass valve, so we are opening the bypass valve for some

designated time and mixing the hot(directed from flow limiter) and cold (PHE

outlet ) flows.

5 .This 300°F temperature air is going to split for three Purpose

a) For

Anti-icing

b) To supply

hot air to cabin(if required)

c) To

refrigeration unit

6. This 300°F air can be directly used for anti-icing and de-icing

purpose. This air will be taken by the tubes and will be sprayed on the leading

edge through suitable arrangements. And one part of the 300°F air flow is

directed to the cabin for hot air supply.

7. Remaining part of the air is directed towards

refrigeration unit for further cooling. On the way there is main control that

is “Main shut off Valve”. This can be directly controlled by the pilot.

8. After main shut off valve there is Refrigeration unit, this

contains

a) Compressor

b) Turbine

c) Water

Separator

Both turbine and compressor are connected by the same shaft.

9. The air flows to the compressor region; there it strikes the

compressor blade and makes rotating at initial. After compressor starts it

compresses the air and Pressurizes the air so some amount of heat may be added

to the air. Then Air is going to the Secondary heat exchanger (SHE), where the

heat from the air is taken by the ram air by convection. The air has been

cooled now.

10. The output of SHE goes to the Turbine. Since because of the

turbine, here the cold gas is allowed to expand, so that pressure drops,

temperature again drops, it may be on some minus °F sometimes.

11. After expansion in the turbine, air which is in a circular

motion is allowed to go for the water separator region for separation of water

particles in the cold air. Since water particles are denser than air they get

attached to the walls of the water separator due to centrifugal force. In some

specified place there are some holes made on the water separator to drain the

water particles attached.

12. In the cabin we need only a temperature range of 60°F-125°F

(15°C-51°C) and a pressure of 3p.s.i. which is suitable for human.

13. By opening and closing the refrigerant bypass valve, we can

mingle the pure cold air and 300°F air, to make a possible living temperature

for human beings.

14. After maintaining to proper temperature and pressure the air

is allowed to go to the cabin by suitable pipelines.

15. If there is any problem on the total system means, we can

directly mix the hot air supply with ram air (which is taken near SHE) and maintain

the proper temperature by proper mixing. But this method is only for emergency

purpose. Please note when using this ram air method of cooling pressurization

should be done separately by cabin superchargers or whatever the device builds

up pressure.

Thanks

ReplyDeleteTq

DeleteGreat Article! I got too much information regards HVAC Services and I will follow this tips. Thanks for sharing such a helpful article. Click here to more information about it

ReplyDeleterent a chiller, When your website or blog goes live for the first time, it is exciting. That is until you realize no one but you and your.

ReplyDelete